Worldpoly News

MAFFRA POLY WITH WORLDPOLY ADDRESS EMERGENCY WELDS

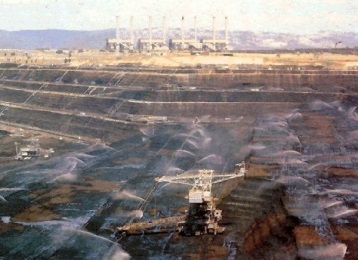

PE pipeline specialist Maffra Poly and Pumps, equipped with a number of Worldpoly machines, has been pivotal in emergency welding at Yallourn Open Cut, Morwell, Australia.

In March 2014, the fiercest of Victoria's 230 summer bushfires raged across a kilometre-and-a-half front in an open-cut coal mine at Morwell, 150km east of Melbourne, Australia. Two helicopters, 46 trucks and more than 200 firefighters fought to contain the blaze, which burned in walls of coal up to 30 metres high.

Fire Services Commissioner Craig Lapsley says there are high levels of carbon monoxide in the pit itself and authorities are also monitoring levels from smoke over Morwell. "It's a fire that's not going to be easy to put out," Mr Lapsley said.

Convesely, Maffra Poly and Pumps were also of service at the Open Cut to help reverse the floodwaters that had broken from Morwell River in February 2013. According to local sources at the time, the river ran backwards for two days as the coal mine began to fill.

|

|

|

In response to both emergencies, regional contractor and PE pipeline specialist Maffra Poly and Pumps furiously welded 630mm and00mm OD polyetheleyle pipe.

Both the Worldpoly WHD630 and Worldpoly Australian-made PolyRover630 AllTerrain machines were used for these projects.

According to Manager Damian Hall (no relation to Worldpoly’s Rob Hall), both types of machine provided far better functionality and more power than was required, allowing rapid mobilisation and the welding of long pipe strings.

"PolyRover630 AllTerrain was easy to use, requiring no special training. Its tough build, coupled with the on-board hydraulics, heating plate and facing tool make it a very productive pipeline tool. We will be using our PolyRover at every opportunity".

The PolyRover and the PolyForce range of machines from Worldpoly encompass clever engineering ingenuity and are proudly manufactured in Worldpoly’s head office factory in Melbourne, Australia.

Tough equipment for a tough world.

For more information, email: sales@worldpoly.com website: www.worldpoly.com

Worldpoly News

- OLDEST CITY BUILDS WASTE WATER TREATMENT PLANT

- THE HDPE FOOT VALVES YOU’VE BEEN WAITING FOR

- APS LAUNCH NEW VICTORIAN FABRICATION LOCATION

- 2500MM SMART BUTT WELDER DELIVERED TO TURKEY

- MP Andrew Robb Opens Myanmar's Welding School

- The Earthmover & Civil Contractor Magazine

- PolyForce Technology Being Exhibited at AIMEX

- Compare the PolyForce630 with the other guys

- New Training Manager - Australia & International

- SEGURIDAD EN LA SOLDADURA A TOPE

- SAFETY in Butt Welding - New Benchmark?

- Worldpoly now operating in 105 countries

- UPCOMING CONFERENCES

- HIGH PRESSURE WELDING-WHERE DID THAT COME FROM?

- ETHIOPIA MAKES 101 FOR WORLDPOLY

- When Failure is Not an Option

- AUSTRALIAN-MADE: POLYFORCE SERIES 2

- MAFFRA POLY WITH WORLDPOLY ADDRESS EMERGENCY WELDS

- EVENT FEB 2014 - BUTT FUSION QUALITY ASSURANCE

- 50 YEARS OF POLY EXPERIENCE AND EXPERTISE

- TOUGH MACHINERY FOR A TOUGH TERRAIN

- AUSTRALIAN-MADE POLYROVER(TM)630

- OMAN BEC WELCOMES WORLDPOLYS GUIDANCE

- ANUNCIO DE OFICINA WORLDPOLY LATINO AMERICA

- BHP BILLITON CHILE STICKS TO WORLDPOLY

- TOUGH ENVIRONMENT? OUR SPECIALITY

- WORLDPOLY PROVIDES WATERTIGHT SOLUTIONS

- WE'VE COPPED A TOUGH NEW LOOK

- WORLDPOLY... CATCH OF THE DAY

Copyright © Worldpoly Australia 2012. ABN 56092 362 260.

Copyright © Worldpoly Australia 2012. ABN 56092 362 260.