Worldpoly News

SAFETY in Butt Welding - New Benchmark?

A recent tragedy in Australia on an imported welding machine has focussed local attention on the safety aspects of automatic welding equipment. As one of the world’s most committed operator health and safety nations; Australia has taken this very seriously.

Operator error is an interesting concept when applied to such accidents, as is the case with motor vehicles. It was not long ago when cars were not fitted with airbags, ABS brakes, impact resistant design, safety steering columns, even power brakes and power steering. Some cars in 2014, park themselves, and soon will be automatically driven using mobile PLCs. In the ‘70s they didn’t even include seat belts, but of course they are standard now.

Today’s Equipment Options:

Todays’ automatic welding equipment design offers a myriad of options to increase the safety of operation. Proxy switches, two-handed operation, inspection cameras, dead-man switches, CAT3 safety shutoff, safety signage, restricted entry space, hydraulic hose wrap and so on.

Which options are applied to equipment comes down to price, and training. Historically, butt welding has been trained generically. Whether it is a 5 day comprehensive DVS course limited to 630mm pipe diameter; an Australian two-day course covering butt welding and electrofusion; or a quick visit by the salesman showing the basics - cross-training and certification has been deemed satisfactory, and probably is, for generic ‘European style’ equipment. This type of equipment has separate components located in the working area, and is the most commonly used. It is also the safest.

For many years another style of equipment has been used in North America, where all components of the machine are fitted in a single assembly. This assembly can be machine only, on a wheeled carriage, or on tracks with its’ own generator. These machines are very handy for long pipelines, or where the welding location will be often relocated. They also have the highest capital cost, so the value equation is up to the location, contractor, available human resources etc.

Considering machine design, traditional butt welding machines have used basic and proven hydraulic design. For top-end machines some manufacturers, including Australian butt welding manufacturer; Worldpoly, use mobile PLC controls to provide the relevant control of pressure, time and temperature. More recently such controls have also been applied to the automatic operation and measurement of drag, heating plate changeover, welding and cooling pressures and times, data logging and remote communication.

Until recently, the single-unit machines have relied on basic controls as have been successful in various modifications for decades. What has been clearly lacking is the use of current technology in not only the welding operation, but operator safety.

New developments in Operator Safety

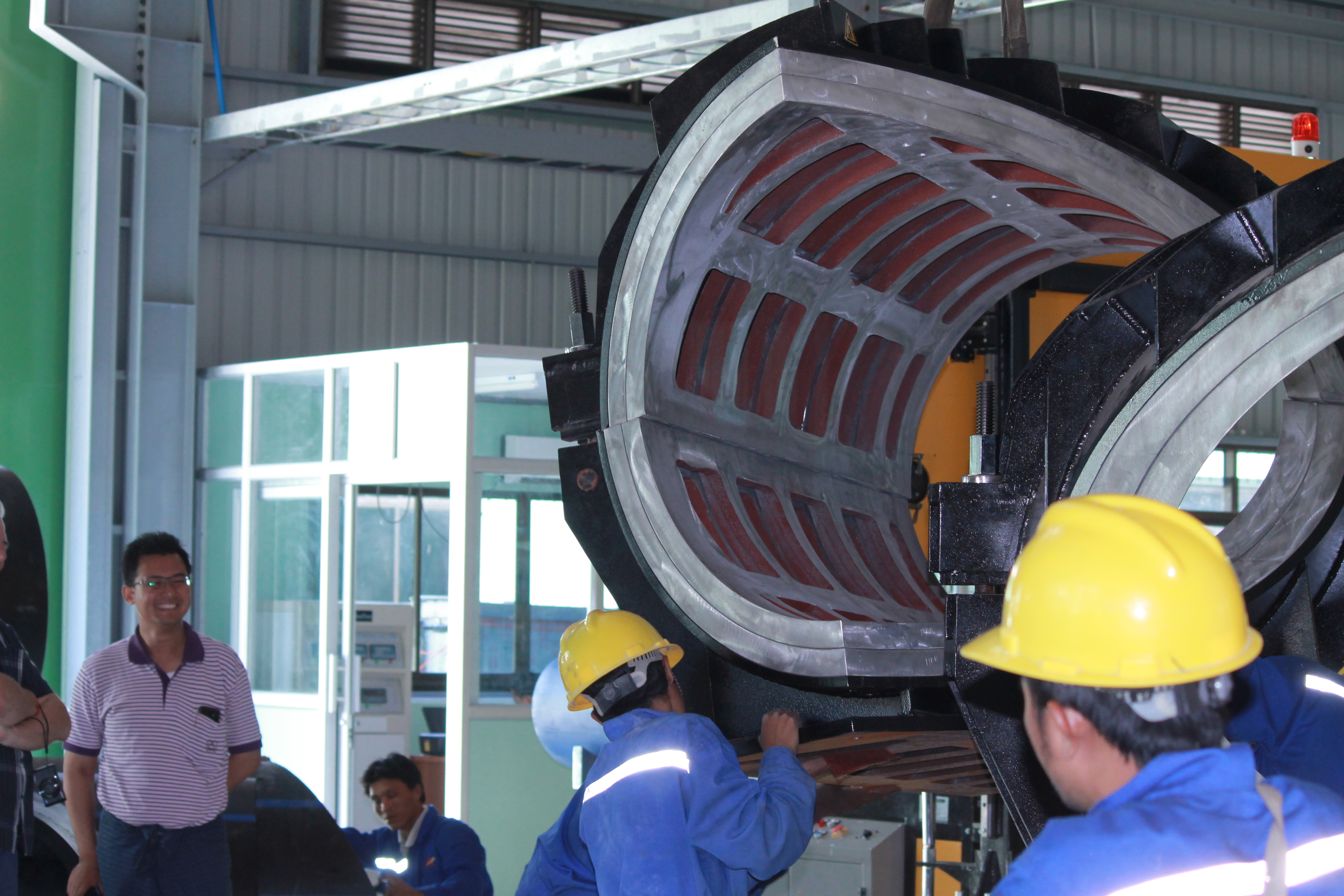

Three years ago Worldpoly began a dedicated research and development project with international leader Bosch Rexroth resulting in a quantum leap in butt welding machine design and operation; using leading edge automation technology. Rexroth embraced this new opportunity and enthusiastically brought their Australian, European and US intellect to the party, resulting in Worldpolys’ PolyForce630 Automated butt welder.

Unlike other machines, PolyForce630 uses Rexroths’ Mobile PLC, the same unit used on underground rock drills and excavators. As an almost indestructible controller, this allows the provision of safety and welding controls previously unavailable.

Two-handed controls are simple to navigate and reduce the likelihood of the operator from multi-tasking. By entering the welding standard (high or low force), pipe OD and SDR or wall thickness, the PLC calculates temperature, time, pressure and drag. Safety push buttons, hydraulic safety lockouts, CAT3 E-stops, 5 Gb of internal memory, the ability data log any number of welds and site parameters and complete site paperwork, all are standard now with options to remotely communicate using GSM, Satellite or Bluetooth in the future. From an operational perspective, it is not possible to crash the heating plate and facing tool with the pipe clamps, and changeover time for 630mm (24”) SDR 11 is consistently 3.5 seconds.

Training

From a safety perspective, all operators should be ideally trained and licenced for that specific butt welding machine. Worldpolys’ PolyForce insists that at the beginning of the shift, the licence number must be entered for the machine to start. Guided by industry needs, Worldpoly is developing a prestart checklist/safety video; where the built in screen will guide the operator through a series of checks or show them a video around the machine, showing what to check and what to be careful of - during welding. The approved operator is then automatically included in the logged data, which is saved to USB (standard) and can then be retrieved by GSM, Satellite or Bluetooth (optional) by the weld, shift, or any period required. The output of the retrieved data can be formatted to automatically complete required site documentation etc. Furthermore individual operator training and licencing is provided for every PolyForce supplied.

If generic training is preferred, the operation of the PolyForce630 is so intuitive that will fit right in with the expectations of both operators and management.

New Safety Benchmark?

It would appear that Australian ingenuity and an inherent respect for operator health and safety has generated a new benchmark in butt welding.

According to Daniel Begley from Bosch Rexroth Australia, “Worldpolys’ Australian-made PolyForce uses todays’ technology in an operator friendly, OH&S conscious and productivity focused package. It has been a pleasure for Bosch Rexroth to work with Worldpoly on the development of this world standard equipment, and to be a part of such a practical application of current technology.”

.jpg)

For more information, email sales@worldpoly.com or visit www.worldpoly.com.au

Worldpoly News

- OLDEST CITY BUILDS WASTE WATER TREATMENT PLANT

- THE HDPE FOOT VALVES YOU’VE BEEN WAITING FOR

- APS LAUNCH NEW VICTORIAN FABRICATION LOCATION

- 2500MM SMART BUTT WELDER DELIVERED TO TURKEY

- MP Andrew Robb Opens Myanmar's Welding School

- The Earthmover & Civil Contractor Magazine

- PolyForce Technology Being Exhibited at AIMEX

- Compare the PolyForce630 with the other guys

- New Training Manager - Australia & International

- SEGURIDAD EN LA SOLDADURA A TOPE

- SAFETY in Butt Welding - New Benchmark?

- Worldpoly now operating in 105 countries

- UPCOMING CONFERENCES

- HIGH PRESSURE WELDING-WHERE DID THAT COME FROM?

- ETHIOPIA MAKES 101 FOR WORLDPOLY

- When Failure is Not an Option

- AUSTRALIAN-MADE: POLYFORCE SERIES 2

- MAFFRA POLY WITH WORLDPOLY ADDRESS EMERGENCY WELDS

- EVENT FEB 2014 - BUTT FUSION QUALITY ASSURANCE

- 50 YEARS OF POLY EXPERIENCE AND EXPERTISE

- TOUGH MACHINERY FOR A TOUGH TERRAIN

- AUSTRALIAN-MADE POLYROVER(TM)630

- OMAN BEC WELCOMES WORLDPOLYS GUIDANCE

- ANUNCIO DE OFICINA WORLDPOLY LATINO AMERICA

- BHP BILLITON CHILE STICKS TO WORLDPOLY

- TOUGH ENVIRONMENT? OUR SPECIALITY

- WORLDPOLY PROVIDES WATERTIGHT SOLUTIONS

- WE'VE COPPED A TOUGH NEW LOOK

- WORLDPOLY... CATCH OF THE DAY

Copyright © Worldpoly Australia 2012. ABN 56092 362 260.

Copyright © Worldpoly Australia 2012. ABN 56092 362 260.